Premium: Measuring density in thickener process

Are you struggling with your thickener operation? Does your thickener underflow contain too much water or do you have too much solid content in the overflow? You are not the only one. End-users in the mineral processing industry are striving for optimal thickener operation, which results in saving water and collecting the highest amount of valuable material for processing. Density plays a crucial factor in reaching these goals. This whitepaper ‘Five reasons for measuring density in thickener underflow’ describes the purposes and benefits of measuring density at different points in thickener tanks. The paper starts with a short introduction to the thickening process, followed by five reasons for density measurement in this separation process.

What is thickenening?

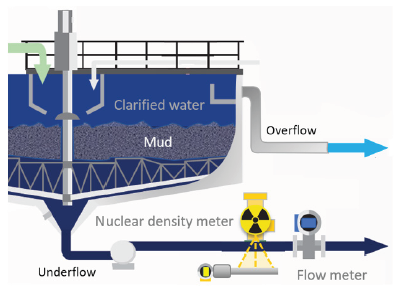

Basically, the thickening process is all about separating a solid-liquid mixture into a dense underflow (a slurry consisting of as many solids as possible) and a clear overflow (ideally, clear water without solids). This separation process is driven by gravity. Because of the gravitation, particles, of different sizes and densities, are creating different layers (settling zones) throughout the tank. These differences are the driving force for the thickening process.

Thickening by sedimentation is applied in the mineral processing industry for product and tailings streams. For tailings, water recovery is required and underflow will be targeted, while in concentrate applications the overflow measurement is essential.

Do you want to read further?

Please subscribe our newsletter to get full text

Want to have frequent updates on our products? Then please subscribe to our newsletter or follow us on our social media accounts at LinkedIn, Twitter and Instagram.

Receive our technical update?

Fill in your name and email address and we’ll keep you in the loop on our latest technology updates.