SLURRY DENSITY METER

The Rhosonics SDM stands for Slurry Density Meter, which is a category of instruments that allows for measuring the density of slurries in real-time. This instrument uses a non-intrusive ultrasonic sensor to measure the real-time density of mineral slurries under high-density levels and at very large pipes. Moreover, the SDMs have a robust design with sensors made of highly abrasion-resistant materials, making them ideal for rough process conditions.

Rhosonics helps mineral processing plants and other industries to replace nuclear density gauges by non-hazardous ultrasonic technology. Consequently, operators can achieve process optimization in a safer, more reliable, sustainable, and cost-effective way. This is how Rhosonics contributes to a greener and smarter industry.

On November 2nd, 2023, Rhosonics released the latest version of the SDM, the SDM ECO. The SDM ECO is an upgrade of the SDM-4 in terms of accuracy, response time, operating temperature range, and sensor design. In addition to that, the SDM ECO can be controlled by a 7’’ touchscreen display, laptop, via optional Wi-Fi, or from anywhere with server access.

Pipe Integration Systems for Slurry Density Meter

Wafer

The UWC, a synthetic flange-like ring made of UHPE, is 60 mm thick and can be clamped between two flanges in almost every piping system.

Spool-piece

A spool, which can be made of HDPE, steel A106/A105, or other steel grades, is a pipe piece that can be mounted between two flanges. This installation method can be optionally available with a PU liner and other liners upon request. Furthermore, the choice of materials can differ depending on the application. The spool-piece is mainly useful with abrasive applications

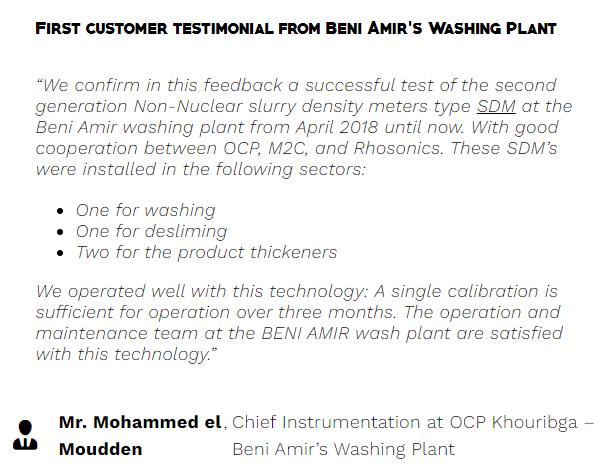

Reviews

Contact us for more information

Phone: +31 341 370 073

Email: sales@rhosonics.com

Get in touch with Rhosonics for further information about density control for efficient mineral processing. If you also want to learn more about our applications, then please also check our case studies and webinars.

For more information about Rhosonics or our ultrasonic analyzers, please take a look at our LinkedIn, Instagram, or Twitter page.