PULP & PAPER

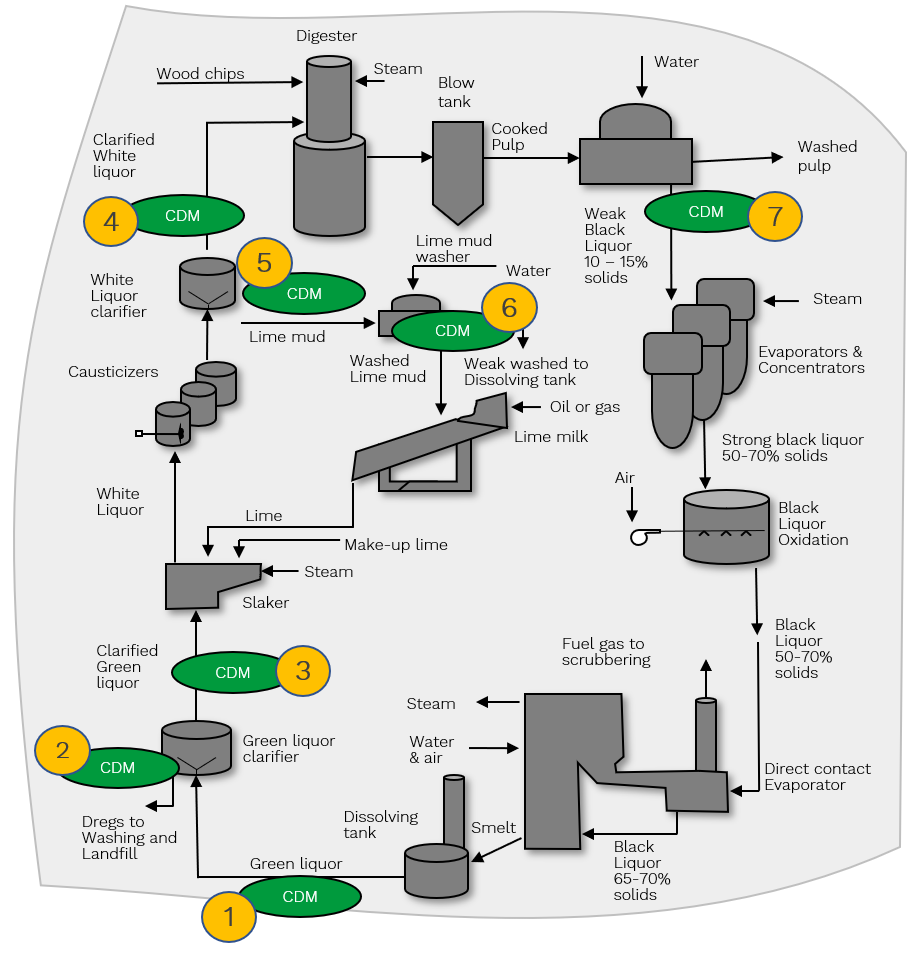

Rhosonics has developed measuring equipment for several applications in the kraft process of the pulp and paper industry. Using a single sensor positioned in line, it is possible to determine the dissolved and non-dissolved components. We have experience in measuring the concentration and density of applications such as weak black liquor, brine and green liquor dregs. Additionally, we can measure the density of lime mud.

1. Controlling the dissolving process of black liquor in water. The green liquor consists of sodium carbonate (Na2CO3), sodium sulfide (Na2S) and a bit of sodium hydroxide (NaOH)

2. Green liquor monitoring after clarifier, the solids are removed

3. Green liquor monitoring

4+5. White liquor monitoring

6. Lime slurry monitoring

7. Weak black liquor (10-15% solids)

Kraft process

The Kraft Process of the pulp and paper industry is all about the conversion of wood into wood pulp. Wood chips are mixed together with white liquor. During this process, black liquor (spent liquor) is then formed, and wood pulp is produced. Black liquor is processed and treated until green liquor is formed. The use of lime milk can turn this green liquor into white liquor again so that it is reusable.

In this process, Rhosonics can measure the green and white liquor accurately. Monitoring the alkali concentration throughout the Kraft Process is important, as is monitoring flow rates, contact time, and ultimate cost-effectiveness of the pulp mill. Our CDM 9670 and 9680 measure TDS (alkali) and TSS (amount of solids). One advantage of using ultrasonic technology is that you can measure two important properties using just a single device, and it also allows for greater accuracy, as well as less maintenance and calibration. In addition, the sensor is also less sensitive to pollution.

PRODUCT CHOICE FOR THIS INDUSTRY

Get in touch with Rhosonics for further information. If you want to learn more about our applications, then please also check our client cases and webinars. For more information about Rhosonics or our ultrasonic analyzers, please take a look at our LinkedIn, Instagram, or Twitter page.