FLAT PANEL DISPLAY

Rhosonics helps the flat panel display industry to use ultrasonic technology for in-line, real-time measurements, through which process optimization is achievable, allowing a safer, more reliable, sustainable and cost-effective operation. This is how Rhosonics contributes to a smart and green world.

Rhosonics Analytical provides solutions for inline analysis in chemical blending. Serving virtually all electronics industries, inline analyzers are available for the following applications.

LCD & TFT productions

Companies widely use Rhosonics inline process analyzers in the production of LCD flat panel displays. Within this industry, companies commonly utilize etchants (ITO-Etch), strippers, and developers (such as TMAH). The industry is increasingly prioritizing the measurement of photoresist.

Rhosonics has developed a special device for measuring TMAH+PR (CCM B32). Companies then utilize strippers to exfoliate photoresist remaining in the photolithography process. Citric acid is often used as a substitute for acetic acid, which typically leaves a strong odor in the darkroom. Rhosonics is able to measure these types of liquids online, including detergents and surfactants.

Photolithography

Concentration measurement is important in the flat panel display process to prevent issues in the cleaning or wet etching processes.

Cleaning step

After the process step, companies must clean the used materials with chemicals to prevent contamination in the next step. The goal of cleaning is to remove residues from the previous steps that could affect the performance of the following steps. In addition, the cleaning chemicals must have the right concentrations to effectively clean the surface of the wafer. Otherwise, the wafers may contain undesirable organic/inorganic materials. Additionally, wafers that have not been properly cleaned will not have the desired quality when the production line is completed. As a result, the product will either be classified as defective or sold as a chip with lower performance.

Development step

Companies develop the exposed wafers in immersion baths or by spraying. Depending on the type of resist (negative or positive), the exposed area is removed or remains. This step is important to create a perfect resist pattern and to control which part of the substrate is etched. The pattern of the positive resist or the negative resist should be the same as the desired one.

Otherwise, the next step removes the wrong areas of the substrate, resulting in an ineffective product. As with any production step in the photolithography process, precision is key to achieving the desired results in the development phase. The concentration of the photoresist developer (e.g. TMAH) should be within an optimal range to effectively remove the photoresist in the intended area.

For example, a typical TMAH solution should have a concentration between 2.38% and 2.62%. An accurate real-time analyzer helps keep chemical properties under control and working effectively.

Wet etching step

Wet etching (or isotropic etching) is a rapid method of etching materials. Companies use various types of chemicals to create a pattern on the substrate of a given material (usually silicon wafers). Currently, there is a trend towards smaller and more compact chipsets, therefore the challenge of this process is to create more precise and complex patterns on the substrate using the right chemical concentrations.

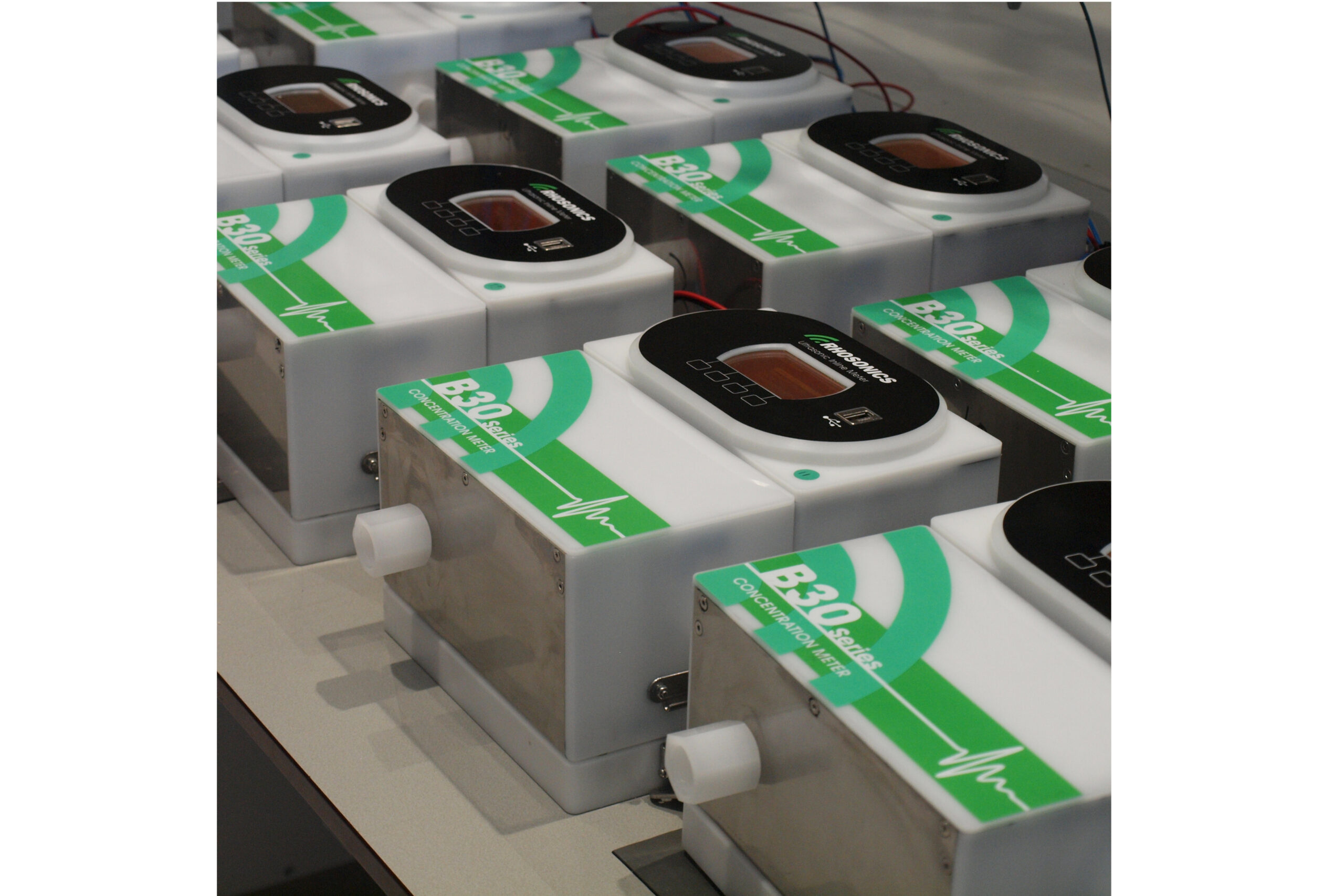

product choice for this industry

Get in touch with Rhosonics for further information. If you want to learn more about our applications, then please also check our client cases and webinars. For more information about Rhosonics or our ultrasonic analyzers, please take a look at our LinkedIn, Instagram, or Twitter page.