Concentration measurement in the copper foil industry

Thursday 14 Apr 2022

Read about the copper foil production process. Discover why the Rhosonics CCM 9580 helps to maintain the desired concentrations to meet the quality standards for efficient copper foil production.

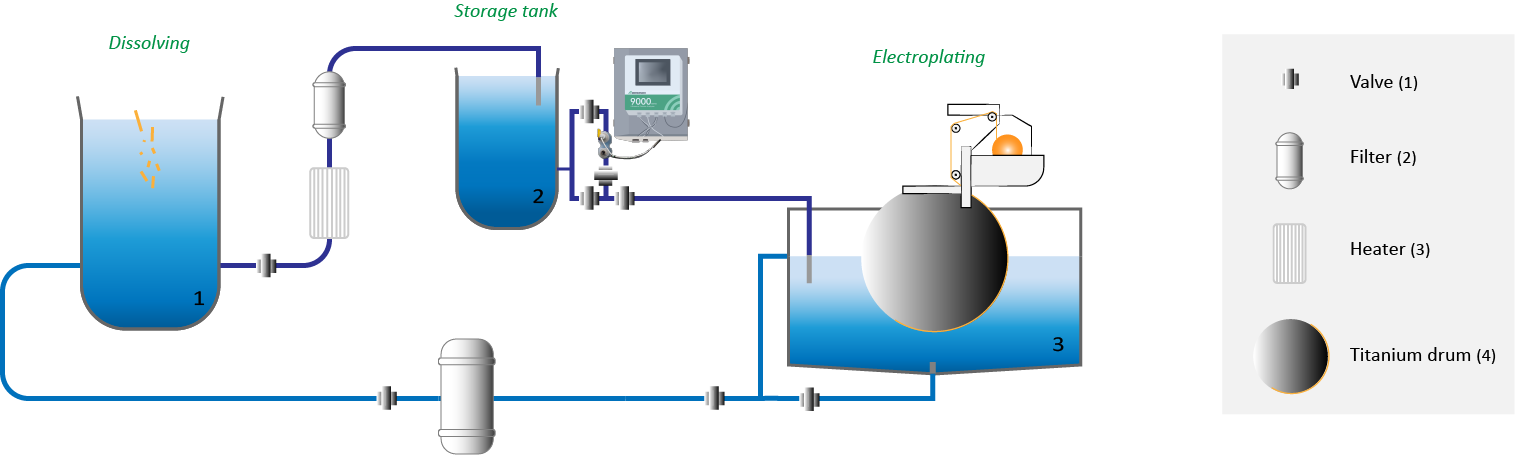

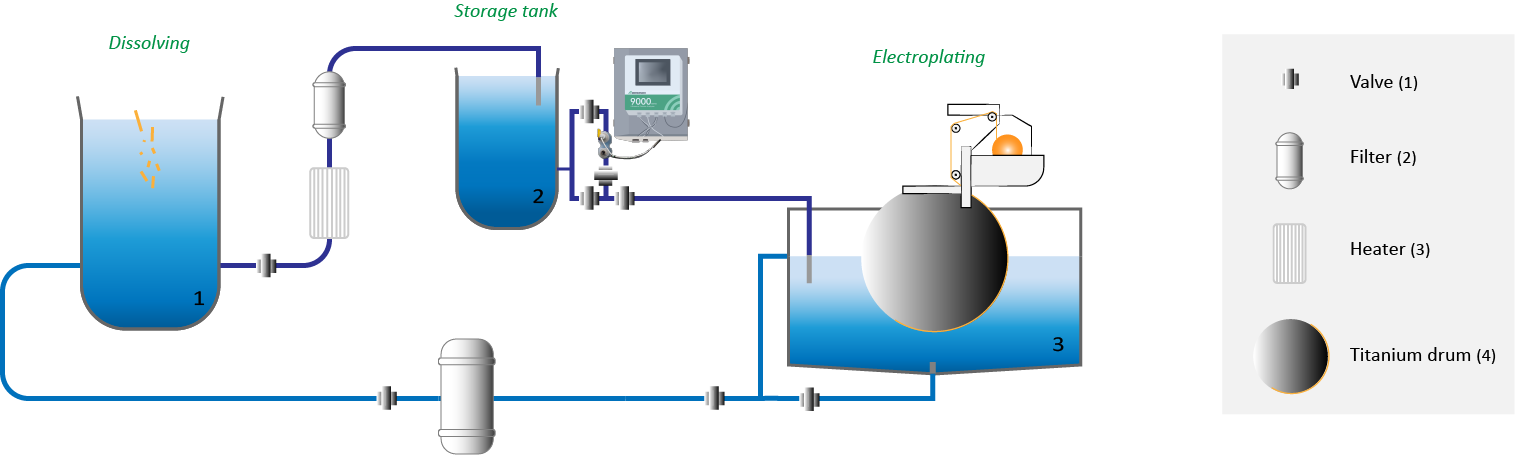

在铜箔生产过程中,首先是将高纯度(回收)铜溶解在硫酸(H2SO4)中。 然后将该溶液泵入过滤器去除杂质,产生所需的高纯度铜电解质溶液。 之后被保存在储存槽。在溶液被送入实际电镀过程,以制造铜箔之前,溶液会被保存在其中。

在该储槽侧面设有再循环旁路中,对两种浓度参数(Cu + H2SO4)进行监测,这是铜箔生产过程中的一项关键量值。当溶液符合所有化学和质量标准时,被泵入大型电镀槽,铜离子会附着到阴极钛辊表面,形成一层非常纯净的铜薄膜。这就是电镀(ED)工艺。

Rhosonics CCM 9580化学浓度计

在溶液进入电镀工序之前,Rhosonics CCM 9580分析仪能精确监测溶解的铜和硫酸溶液(H2SO4和Cu++)浓度。该产品使用两个传感器(超声波和电导率)实时测量两种浓度。浓度监测是在储存槽的旁路中完成的。分析仪根据多项式模型来计算这两种浓度(参见下面的校准矩阵)。除了这两种浓度的持续性数据外,Rhosonics CCM 9580还提供实时温度读数。

通过这种方式,Rhosonics CCM 9580分析仪能帮助客户控管所需浓度,以满足高效铜箔生产的质量标准。

Copper foil application

One of the initial stages in the copper foil production process involves dissolving high-grade (recycled) copper in Sulfuric Acid (H2S04)(1). The solution is then pumped through filters to produce the desired copper electrolyte solution and remove impurities. The final stage is a storage tank, where the solution is kept before it is fed into the actual plating process to create copper foil(2).

A critical measurement in the production process of copper foil is monitoring both concentrations (Cu + H2SO4) in a recirculated bypass on the side of the storage tank. When the solution meets all chemical and quality standards, it is pumped into large plating tanks containing partially immersed titanium drums to create a thin film of very pure copper. These tanks are also known as electroplating (ED) machines(3).

The Rhosonics CCM 9580 chemical concentration meter

The Rhosonics model CCM 9580 analyzer accurately monitors the solution of dissolved Copper and Sulfuric Acid (H2SO4 & Cu++). Measurement in copper-foil is done before the electroplating process. This model uses two sensors (ultrasonic & conductivity) to measure both concentrations in real-time. This is done in the bypass of the storage tank. The analyzer uses a predefined polynomial to calculate both concentrations (see the calibration matrix below). Besides continuous information about the two concentrations, the Rhosonics CCM 9580 also provides a real-time temperature reading.

In this way, the Rhosonics CCM 9580 model helps the client to maintain the desired concentrations to meet the quality standards for efficient copper foil production.

Want to have frequent updates on our products? Then please subscribe to our newsletter or follow us on our social media accounts at LinkedIn, Twitter and Instagram.

Receive our technical update?

Fill in your name and email address and we’ll keep you in the loop on our latest technology updates.