Enhancing Measurement Accuracy with Multi-Point Calibration

Wednesday 11 Sep 2024

At Rhosonics, we understand that accuracy is paramount in many industries. That’s why we’re constantly striving to improve the performance of our measurement solutions. The incorporation of Multi-Point Calibration (MPC) into our SDM ECO represents a significant step forward in this pursuit, addressing the limitations of traditional calibration methods and providing our customers with a more versatile and powerful tool for achieving accurate measurements.

The Shortcomings of Span Calibration

Traditional Span Calibration operates under the assumption of linearity between measured variables. The accuracy of Span Calibration on the SDM ECO is tied to the specific temperature at which it was performed, and its reliance on measurements at only two points makes it susceptible to noise and other anomalies. This can be a major drawback when dealing with the complexities of real-world industrial processes, where factors like temperature fluctuations and the inherent non-linearity of certain fluids can lead to measurement inaccuracies. Additionally, Span Calibration struggles to accurately account for how the density of a fluid changes with varying temperatures.

The Advantages of Multi-Point Calibration (MPC)

MPC overcomes these limitations by incorporating multiple calibration points across a range of temperatures and densities. This approach allows us to create a more sophisticated calibration curve that accurately reflects the behavior of the system under various conditions. By considering both temperature and acoustic impedance in its mathematical model, MPC provides a more precise fit to the actual behavior of the fluid being measured, especially for non-linear measurements involving substances like slurries.

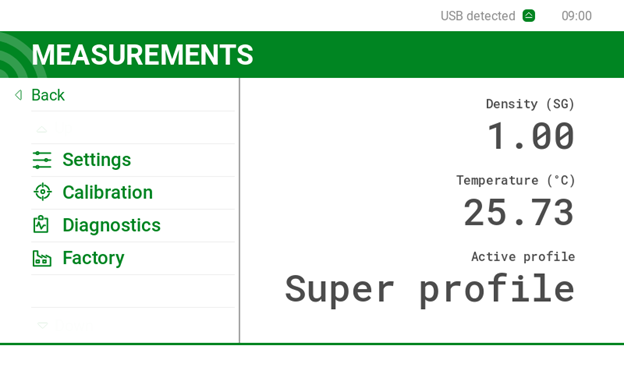

The integration of MPC into the SDM ECO significantly enhances its measurement capabilities, ensuring exceptional accuracy across a wider spectrum of industrial applications. Moreover, the SDM ECO comes pre-calibrated on water, providing a reliable baseline and making it ready for further calibration to your specific liquids, ensuring optimal performance right from the outset.

How Multi-Point Calibration Works

MPC operates by collecting hundreds of measurements over a defined period. This extensive sampling process helps to mitigate the impact of noise and ensures a more robust and accurate calibration than can be achieved with the previously utilized two-point calibration. The collected data is then used to generate a calibration curve that accurately represents the system’s behavior under varying conditions.

For complex fluids like chemical slurries, where linear approximations are inadequate, MPC employs higher-order polynomials to fit the data, capturing the non-linear relationships between variables. This results in a more accurate calibration that can adapt to the dynamic nature of industrial processes.

Setting up MPC on the SDM ECO

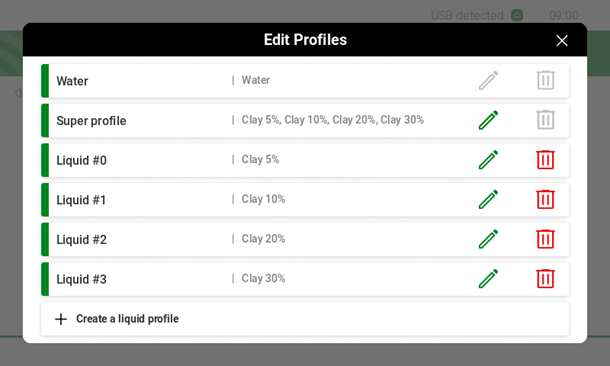

The SDM ECO’s interface streamlines the MPC setup process. The user creates “Liquid Profiles” for specific substances, which can be combined into a “Super Profile” to accommodate broader concentration ranges. The system then guides the user in adding calibration points at recommended temperatures, ensuring accurate measurements across varying conditions. Once the desired temperature is reached, the user can input the corresponding sample density value when available.

It’s important to note that an external device will be required to measure the density of the sampled liquid at each calibration point. Once these density values are obtained, the liquid calibration is complete.

Current users should remember they may need to upgrade the software to the latest version to use MPC calibration.

Conclusion

The Multi-Point Calibration feature on the SDM ECO is a user-friendly and powerful tool designed to provide our customers with exceptional measurement accuracy. By simplifying the calibration process, we allow users to focus on their core operations with confidence in the reliability of their data. This feature enhances the accuracy, consistency, and versatility of our devices, empowering customers to optimize their performance and achieve better results in their operations.

Want to have frequent updates on our products? Then please subscribe to our newsletter or follow us on our social media accounts at LinkedIn, Twitter and Instagram.

Receive our technical update?

Fill in your name and email address and we’ll keep you in the loop on our latest technology updates.