Mine Tailings: The Cornerstone of Safe Mining Operations

Friday 29 Mar 2024

Mine Tailings: The Cornerstone of Safe Mining Operations

In the mining industry, where precious minerals and resources are extracted from the depths of the earth, a significant byproduct arises – mine tailings. These tailings demand rigorous management strategies to safeguard the environment, surrounding communities, and the long-term sustainability of mining operations. In this comprehensive guide, we delve into the intricacies of mine tailings, including what they are, how they’re stored and managed, and the critical role of density management in ensuring the safe containment of these waste materials.

What are Mine Tailings?

In mining, tailings refer to the residual waste material that remains after the desired minerals have been separated from the ore during the mining process. These typically consist of finely ground rock particles, water, and traces of chemicals used in the extraction and separation processes. Often resembling a slurry or thick liquid mixture, they require proper containment and management to prevent environmental contamination and potential hazards to human health and ecosystems. The Society for Mining, Metallurgy & Exploration recognizes tailings management and storage as an essential part of the mining process.

The Challenge of Tailings Management

One of the most common methods for managing mine tailings is the construction of tailings ponds or tailings storage facilities (TSFs). These large-scale repositories serve as containment areas for the collected material, allowing for the settling of solid particles and the retention of water before eventual disposal or treatment. However, the sheer volume and potential hazards involved necessitate stringent monitoring and management protocols to ensure the integrity and stability of these storage facilities.

The method of storing tailings, the waste materials left over after the valuable parts of mined ore have been extracted, varies based on several factors. The local geography, precipitation levels, seismic activity in the region, the specific mineral being extracted, and the proximity of the mine to residential areas all play a role in determining the most suitable storage approach. Each storage facility has its own unique characteristics, necessitating a tailored solution rather than a universal one-size-fits-all approach.

Global Tailings review has a fantastic article that goes more in depth on the types of tailings storage facilities that exist.

The Importance of Density Management

Safe management of mine tailings is centered on controlling and monitoring variables such as their rheology and density. Maintaining optimal density levels ensures proper settling of solids, minimizes the risk of liquefaction (a phenomenon where solid particles become suspended in water, causing the slurry to behave like a liquid), and prevents the formation of unstable zones within the tailings deposit.

Inadequate density management can lead to a cascade of issues, including:

- Improper solid-liquid separation, resulting in excessive water retention and increased storage requirements.

- Formation of unstable zones or pockets within the tailings deposit, compromising structural integrity.

- Increased risk of liquefaction, which can trigger catastrophic tailings dam failures.

Preventing Disasters with Density Monitoring

The consequences of inadequate density management can be catastrophic, as evidenced by past incidents of tailings dam failures. These failures can result in the sudden and uncontrolled release of vast quantities of tailings slurry, leading to devastating environmental impacts, potential loss of life, and severe economic repercussions for mining companies and surrounding communities.

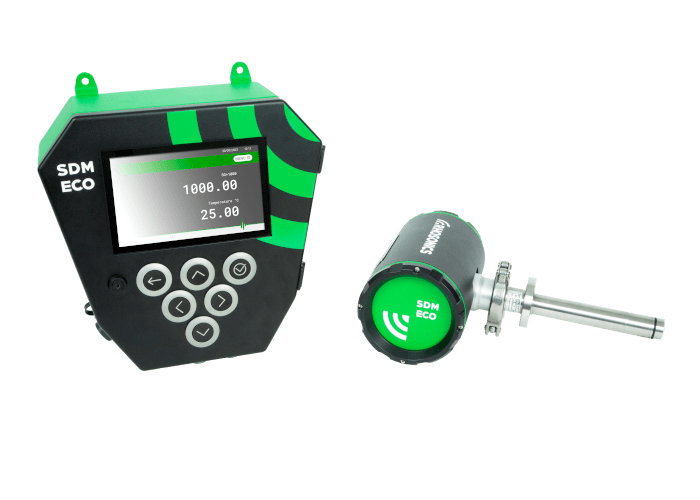

To help mitigate such risks, advanced monitoring technologies, such as the SDM ECO density meter developed by Rhosonics, offer invaluable support in the proactive management of tailings density.

The Role of SDM ECO in Ensuring Safety

The SDM ECO density meter serves as a critical tool for real-time density monitoring from tailings disposal facilities. By accurately measuring the density of the slurry as it enters the storage facility, the SDM ECO provides mining operators with essential data for optimizing density levels and detecting potential anomalies. This proactive approach enables timely interventions to prevent overloading, settling issues, or other factors that could compromise the integrity of the tailings storage facility.

Some key advantages of the SDM ECO density meter include:

- Accurate and Reliable Measurements: Utilizing advanced ultrasonic technology, the SDM ECO provides accurate and reliable density measurements, even in challenging environments.

- Real-time Monitoring: Continuous monitoring capabilities enable mining operators to detect and respond to changes in tailings density promptly, minimizing the risk of potential issues.

- Abrasion Resistant Sensors: The SDM ECO features abrasion resistant sensors, allowing it to withstand the harsh conditions present in tailings slurry streams.

Conclusion

Mine tailings represent a significant challenge for the mining industry, requiring careful management to prevent environmental harm, ensure community safety, and maintain regulatory compliance. Effective density management is also crucial for maintaining the stability and integrity of tailings storage facilities, thereby mitigating the risk of disasters such as tailings dam failures and their devastating consequences.

With advanced technologies like the SDM ECO density meter, mining operators can proactively monitor and control tailings density upstream from disposal facilities. This proactive approach not only enhances safety but also promotes more sustainable mining practices, reduces water usage, and fosters long-term environmental stewardship.

Want to learn more about the SDM ECO? Click here to go to our product page.

Want to have frequent updates on our products? Then please subscribe to our newsletter or follow us on our social media accounts at LinkedIn, Twitter and Instagram.

Receive our technical update?

Fill in your name and email address and we’ll keep you in the loop on our latest technology updates.