SDM at Hopper Dredger

Measuring Task

Determination of sludge density behind the suction pump of the hopper dredger.

-

Hopper capacity: 950 m³

- Pipe diameter: 508 mm (20 inch)

- Pipe material: Steel

- Solids: 10 – 35 wt%

- Density: 1 – 1.4 ton/m³

- Temperature: 5°C – 25°C (41°F – 77°F)

Challenge

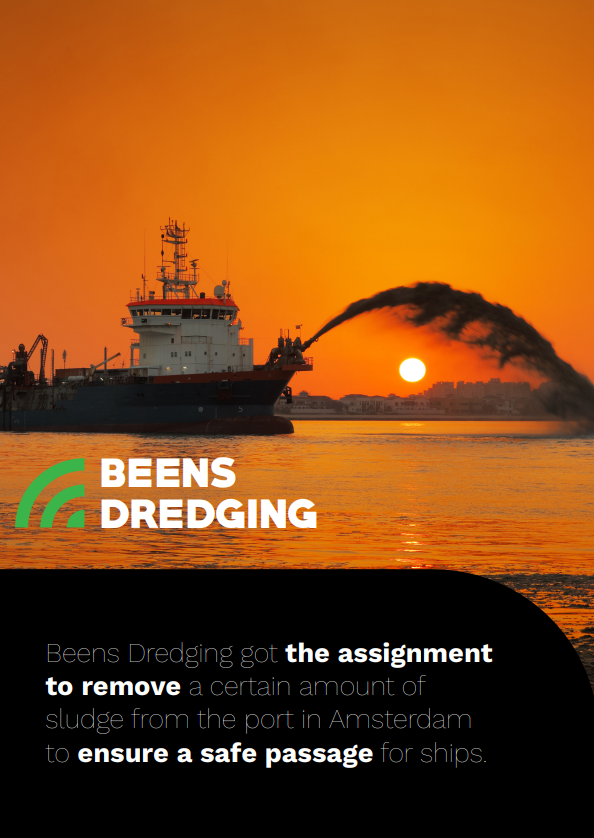

Beens Dredging got the assignment to remove a certain amount of sludge from the port in Amsterdam to ensure a safe passage for ships. The operator of the ship wants to fill the hopper dredger with sand as quickly as possible to reduce the total time spent on this project. A density meter was needed to monitor the real-time density of the sludge.

Solution

The SDM is a good solution for this measuring task, because of its reliable, stable and real-time measurement results. The instrument uses non-nuclear technology, so there are no additional safety costs or governmental restrictions.

The density meter is used in combination with a flow meter to determine the optimal dredging condition. The density and flow rate are both shown at a (digital) cross meter in the wheelhouse. This cross meter helps the operator to execute a dredging session more efficiently, resulting in a reduction of the total project time and accordingly also the costs.

Results

The SDM contributes to:

-

Real-time density monitoring

- Determination of the optimal dredging condition

- Efficient completion of the dredging session

- Reduction of time and money spent on a project

- Quicker response to changing process conditions

- Avoiding pump obstructions

You can read the whole story about the success of Beens Dredging in the case study. Click on the image below to download it.

Get in touch with Rhosonics for further information about chemical concentration or density control. If you want to learn more about our applications, then please also check our client cases and webinars.

Want to have frequent updates on our products? Then please subscribe to our newsletter or follow us on our social media accounts at LinkedIn and Facebook.

Receive our technical update?

Fill in your name and email address and we’ll keep you in the loop on our latest technology updates.