TUNNELING

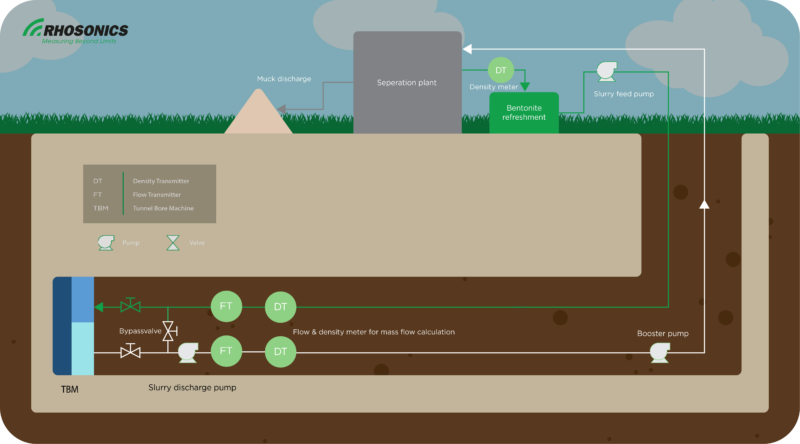

The first aspect of tunneling is to drill a sewer. The cutter head is filled with a slurry (suspension of Bentonite/clay and water) which applies hydrostatic pressure on the excavation face.

During drilling, ‘clean mud’ (water with Bentonite) is pumped from the clean mud tank into the drilling pipe and comes out at the drilling head. The ‘dirt mud’ comes back into the drilling well (starting point). When the drilling well is almost full, it will be pumped into the Recovery Unit (RU) where the operators optimize the recovery of the Bentonite. Bentonite is absorbing sand particles, therefore the slurry can flow easily with water. One Bentonite particle can be recovered five times.

By controlling the wt% solids, the operator is able to optimize the recovery of the Bentonite.

The SDM (Slurry Density Meter) is perfectly suitable for this application. Also, this non-nuclear SDM is a sustainable, non-hazardous solution.

product choice for this industry

Get in touch with Rhosonics for further information about chemical concentration or density control. If you want to learn more about our applications, then please also check our client cases and webinars.

Want to have frequent updates on our products? Then please subscribe to our newsletter or follow us on LinkedIn.