SDM at Rio Tinto Gove Australia

Introduction

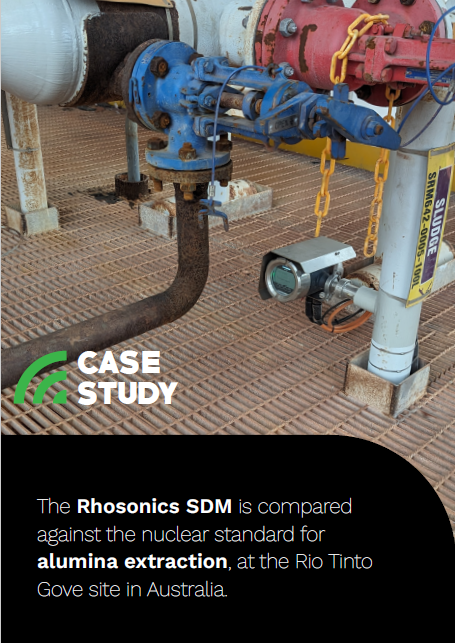

Rio Tinto Gove, a prominent alumina extraction facility, recognized the need to optimize their process efficiency while prioritizing safety and reliability. This case study delves into their journey of implementing Rhosonics SDM (Slurry Density Meter) technology to revolutionize density measurement in their mud extraction process, replacing traditional radioactive density meters for a safer and more accurate solution.

Results

Since the installation of Rhosonics SDM, Rio Tinto Gove has experienced significant improvements in process control and efficiency. Real-time interpretation of trended data has replaced labor-intensive sampling processes, enabling timely adjustments and enhancing the quality of mud supplied to various parts of the plant. This has resulted in increased operational efficiency, reduced downtime, and improved overall productivity.

You can read the whole story in the case study. Click on the image below to download it.

Get in touch with Rhosonics for further information about chemical concentration or density control. If you want to learn more about our applications, then please also check our client cases and webinars.

Want to have frequent updates on our products? Then please subscribe to our newsletter or follow us on our social media accounts at LinkedIn and Facebook.

Receive our technical update?

Fill in your name and email address and we’ll keep you in the loop on our latest technology updates.