CHEMICAL DENSITY METER

Rhosonics CDM stands for Chemical-based slurry Density Meter, which is a category of instruments that allows for real-time density measurement. The CDMs have a robust design that uses sensors made of highly corrosion and abrasion-resistant materials, enabling them to withstand rough process conditions.

In various industries, the Chemical Density Meters are used whenever there is a requirement for measuring chemical-based slurries or liquors. Some of the sectors where this technology is used are Mining, Ore refineries and Pulp & Paper.

About the Chemical Density Meter

CDM 9670

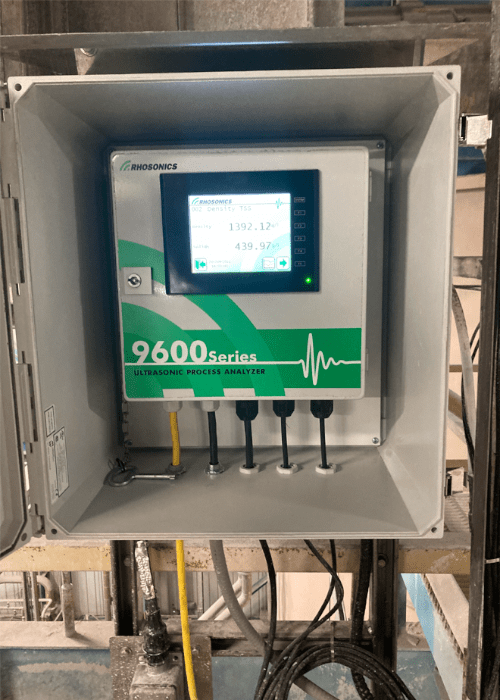

For in-line measurement of TSS (Total Suspended Solids) or TDS (Total Dissolved Solids), we recommend the use of our Chemical Density Meter 9670. Also, the CDM 9670 is ideal for monitoring slurries in a small pipeline. Model 9670 uses two hybrid PEEK sensors, facing opposite directions. In addition, these ultrasonic sensors measure a wide range of physical parameters, including density and the velocity of sound to determine the amount of either dissolved or suspended solids. Thanks to the powerful sensors virtually all slurries up to 2500 g/l are measurable.

CDM 9680

Chemical Density Meter 9680 offers real-time information about multiple parameters of liquids or slurries. However, only one sensor can measure the dissolved solids (TDS), suspended solids (TSS), and density at the same time by reflection technology. Additionally, the sensor can withstand rough conditions of chemicals and mineral slurries thanks to the corrosion and abrasion-resistant sensor materials.

During the process, it is possible to install the CDM 9680 in a tank or in a pipe with a small diameter. However, for larger pipe diameters, the requirement is to use a different analyzer, CDM 9670. Besides, this analyzer has two sensors for transmissive measurement offering the same measurement parameters.

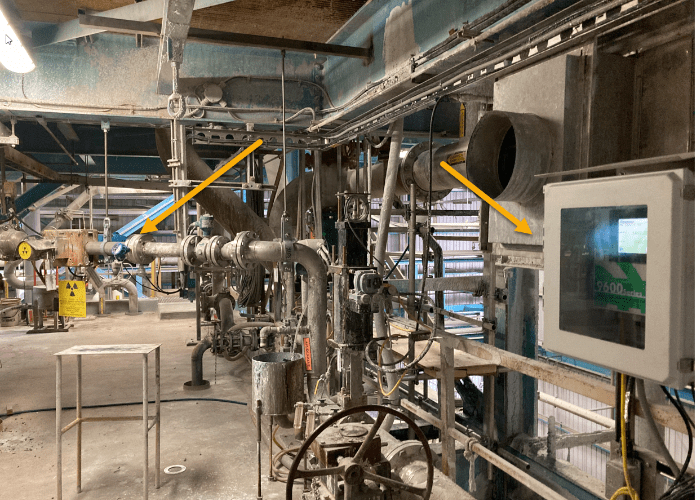

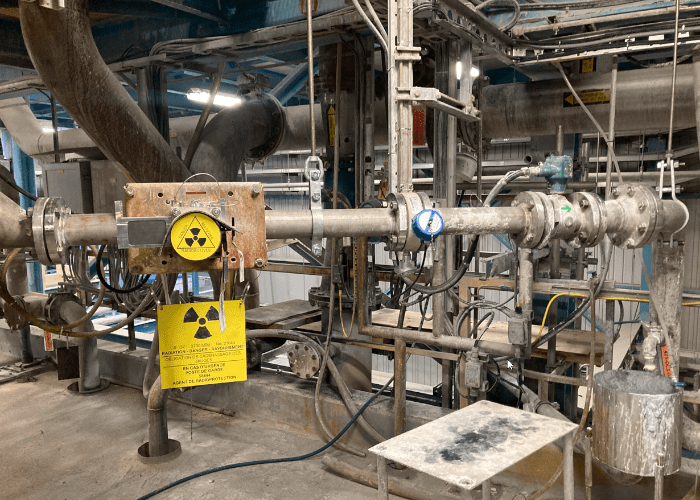

Installation Chemical Density Meter

In terms of configuring the Chemical Density Meter, there are several options available to suit the customer’s specific needs

Chemical Density Meter 9670

The CDM 9670 is easily installed in pipelines, by mounting the sensors onto a metal UFTC spool piece or with a flow-through wafer. Moreover, in both installation methods, there will be zero intrusion of the ultrasonic sensors in the process liquid or slurry.

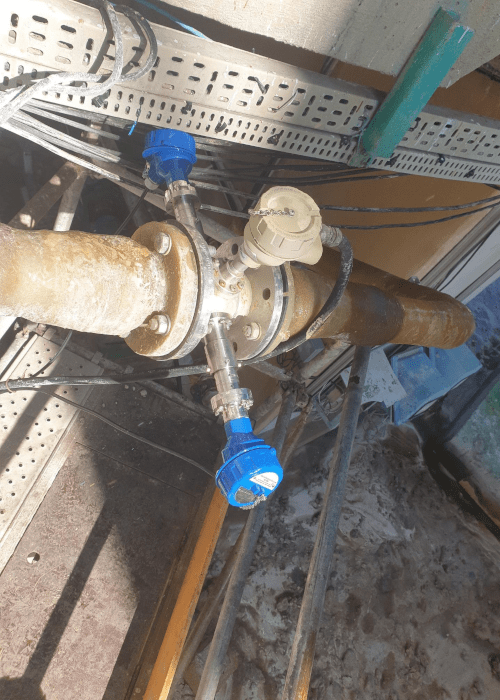

Chemical Density Meter 9680

Tank installation can be accomplished through a UTP tank sensor or UHP insertion probe. The UTP probe can be mounted on top of the tank or in an open channel, while the UHP probe is best used for side-mounted installation.

Alternatively, pipe installation can be done by using a metal pipe piece (UFTC spool) or a PEEK wafer (UFTW). Both methods use a single sensor that measures the sound velocity after reflection at the pipe wall. However, for pipes with a larger diameter, it is recommended to use the CDM 9670 instead.

Contact us for more information

Phone: +31 341 370 073

Email: sales@rhosonics.com

Get in touch with Rhosonics for further information about density control. If you want to learn more about our applications, then please also check our case studies and webinars.

For more information about Rhosonics or our ultrasonic analyzers, please take a look at our LinkedIn page.